Pros and cons of engineered hardwood flooring

If you’re looking to add warmth, refinement and beauty to your facility, nothing compares to authentic wood floors. And when you’re considering wood flooring, two options likely come to mind: solid or engineered.

Engineered hardwood flooring faces the common misconception of being lower quality. In actuality, this option maintains the elegant look and feel of solid wood while providing improved versatility and durability. Further, engineered hardwood flooring offers straightforward installation and cleaning for your facility.

In this article, we’ll examine the pros and cons of engineered hardwood flooring through the lens of material cost, installation, durability and maintenance.

Engineered hardwood cost

Engineered hardwood and solid hardwood are comparatively close when it comes to cost. The precise amount, of course, depends on a variety of factors such as project complexity, location and design.

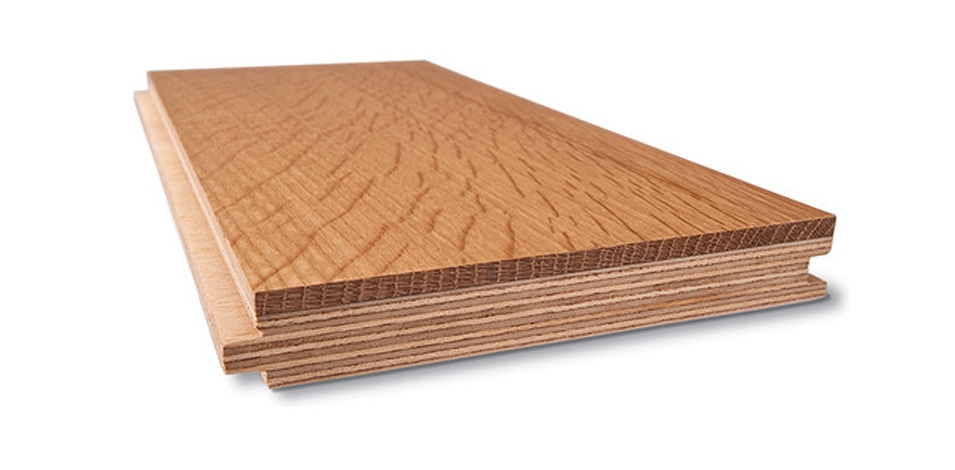

But generally speaking, engineered wood tends to cost less than hardwood because only the top veneer of the product is constructed with the desired species, such as maple or oak. The rest, made up of 3-9 ply layers of hardwood or soft plywood, is typically a recycled product and thus lowers the price of the material (not to mention giving your project an edge in sustainability).

Other cost components such as labor, repair or removal and transporting and storing materials will depend on the installation, which we’ll cover next.

Installation considerations

Engineered hardwood can be nailed down, glued down or installed as a floating floor, providing great versatility for your flooring installation. Further, engineered hardwood is designed to go places that solid wood simply cannot go due to moisture problems, such as directly over a concrete sub-floor.

Solid hardwood, on the other hand, must be installed over a prepared subfloor. For instance, if you want to install ¾” nailed down, field-finished wood, you’ll first need to put down ¾” plywood and ¾” insulation on top of the plywood — only then can you begin to install the actual solid hardwood flooring. This additional material, labor and time can increase the project cost significantly.

Even with these advantages, engineered wood is still not a cure-all for the common moisture and humidity problems that can affect wood-based flooring. In this next section, we will go into the durability and moisture susceptibility of engineered hardwood.

Durability and moisture resistance

Engineered hardwood flooring is comprised of multiple layers of wood that are fused together to support stability. Those layers are designed to be more resistant to higher moisture levels than solid wood. Therefore, your engineered wood flooring won’t expand or contract as easily due to changing temperatures or humidity.

However, greater resistance does not mean engineered hardwood is completely impervious to moisture.

As Jon Namba said in Floor Covering Installer, “It’s still a wood product and it’s still going to expand and contract.” In fact, the “most frequent cause of delamination of an engineered floor is improper relative humidity levels,” said Luc Robitaille in Floor Trends Magazine.

What does this mean for your engineered flooring product and its durability?

It’s still a great option for installing wood flooring in areas where you wouldn’t be able to install solid wood. But, you should still be diligent about moisture: To make sure the subfloor is protected from moisture, loop in your flooring contractor to test the underlying concrete slab for any moisture issues. That way, you can protect your warranty, prevent buckling or warping and ensure a lifetime of reliable performance.

Finally, it’s important to note that most engineered wood will arrive on site with a factory-applied finish, giving it a leg up on durability compared to field-applied finishes for solid wood. The flooring can also be refinished one to two times over its lifespan; this is a great sustainable alternative to replacing and can offer up to a 92 percent reduction in carbon footprint versus replacing.

All in all, engineered hardwood offers improved durability over solid wood while still providing the signature wood flooring aesthetic.

Maintenance best practices

Establishing a thorough cleaning and preventative routine will help maintain your floor over its lifespan. Solid hardwood and engineered hardwood actually require similar attention and upkeep.

The best practices are straightforward:

- Keeping hardwood free from dirt and dust. This will prevent abrasive particulates from scratching the surface.

- Using a broom, vacuum or dry microfiber dust mop to remove debris; microfiber in particular is great for gathering dirt and dust without risking surface damage.

- Dealing with spills immediately, as sitting liquids can lead to irreversible damage to the veneer.

- Avoiding wax-based cleaners or harsh chemicals that might harm the floor’s finish. Instead, rely on manufacturer-recommended liquid cleaners.

- Using entrance mats and area rugs to help eliminate outside dirt while keeping your floor safe.

For further guidance on engineered hardwood flooring maintenance, visit our product care page.

Still have questions about engineered hardwood?

Selecting a best-fit flooring material is an important undertaking. Understanding the pros and cons will help protect both your flooring system and your investment.

The next step? Take your questions to a flooring expert.

At Spectra Contract Flooring, we’ve installed nearly every type of commercial flooring across 400,000 installations and counting. We can show you samples and help you select the best floor for your budget, design vision and environment. Start a conversation with a commercial flooring expert.

A buyer’s guide to commercial flooring

How to get the greatest-value floor and select the right contractor for your project.